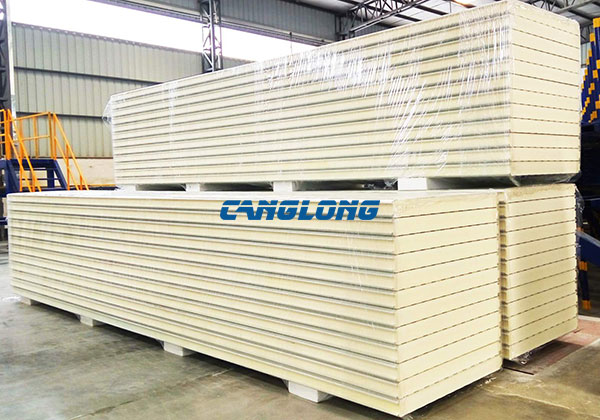

Machine-made cold storage panels PK traditional cold storage panels

With the continuous advancement of refrigeration technology and the increasing development of cold chain logistics, cold storage plays an increasingly important role in ensuring food safety and improving logistics efficiency. In the construction of cold storage, the selection of cold storage panel has become a crucial link. Machine-made cold storage panels and traditional cold storage panels are the two mainstream products on the market, each with its own characteristics. So, who is the standard configuration of cold storage? The following will compare and analyze these two cold storage panels from multiple angles.

1. Insulation performance

Thermal insulation performance is an important indicator to measure the quality of cold storage panel. The machine-made refrigerated storage panels adopt advanced production technology and equipment. By precisely controlling the foaming process, a uniform closed-cell structure is formed inside the panels, thus having excellent thermal insulation performance. In contrast, although traditional cold storage panels also have certain thermal insulation properties, due to limitations in the production process, their closed cell ratio and thermal insulation effect are often not as good as those of machine-made cold storage panels. Therefore, in terms of thermal insulation performance, machine-made refrigerated storage panels have more advantages.

2. Convenience of installation

The ease of installation is an important factor affecting the efficiency and cost of cold storage construction. The machine-made refrigeration storage board adopts a modular design, which is easy to assemble and does not require on-site pouring, which can greatly save installation time and cost. At the same time, the machine-made refrigeration storage panels have precise dimensions and stable quality, which can ensure the accuracy and reliability of installation. However, traditional cold storage panel need to be poured on site. The installation process is cumbersome, takes a long time, and is easily affected by human factors. Therefore, in terms of installation convenience, machine-made refrigeration storage panels also have advantages.

3. Environmental protection

Environmental protection is one of the important standards of modern architecture. The machine-made cold storage panel use environmentally friendly raw materials and processes during the production process, which does not produce harmful substances and meets the requirements of green environmental protection. At the same time, the long service life of machine-made refrigeration storage panels can reduce the frequency of maintenance and replacement, thereby reducing the impact on the environment. Traditional cold storage panels may produce certain pollution during the production process, and their service life is relatively short, requiring frequent maintenance and replacement, which puts a certain amount of pressure on the environment. Therefore, in terms of environmental protection, machine-made cold storage panels are better.

4. Comprehensive cost

In addition to the above three aspects, the overall cost is also an important factor to consider when choosing cold storage panels. Although the initial investment of machine-made cold storage panel may be slightly higher than that of traditional cold storage panels, due to their excellent thermal insulation performance, ease of installation, and environmental protection, they can bring long-term energy savings and lower operating costs. In contrast, although traditional cold storage panels may have advantages in initial investment, they may face higher energy consumption and maintenance costs in long-term operations. Therefore, from a comprehensive cost perspective, machine-made refrigerated storage panels have more advantages.

To sum up, machine-made cold storage panels are superior to traditional cold storage panel in terms of thermal insulation performance, ease of installation, environmental protection and overall cost. Therefore, it can be considered that the machine-made refrigeration storage board is the standard configuration of the cold storage. Of course, in actual applications, selection needs to be made based on specific needs and conditions. For example, in some special environments, specific cold storage panel materials or structures may need to be used to meet specific requirements. But in any case, machine-made cold storage panels, as an advanced cold storage building material, deserve our more attention and promotion.