Sandwich panels of choice when building prefab hangar roofing

With industrial development and technological progress, prefabricated hangars are increasingly used in aviation, aerospace, military and other fields. As an important part of the prefab hangar, the material selection and structure of the roof are crucial. This article will focus on the roofing sandwich panels required when building prefabricated hangar and their characteristics.

1. Types of sandwich panels

The sandwich panel is a composite panel made of two layers of metal panels with thermal insulation and sound insulation materials sandwiched between them. According to different core materials, sandwich panels can be divided into the following types:

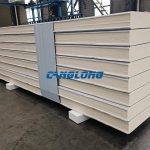

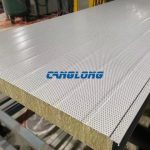

- Polystyrene (EPS) sandwich panel: EPS core material has good thermal insulation properties and is relatively cheap, so it is widely used in prefabricated hangar roofing.

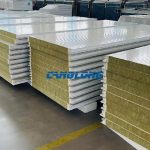

- Rock wool sandwich panel: Rock wool core material has excellent thermal insulation and sound insulation properties, as well as good fire resistance, and is suitable for hangars with high fire protection requirements.

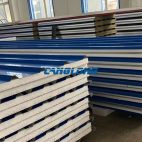

- Polyurethane (PU) sandwich panel: PU core material has extremely high thermal insulation performance and good sound insulation effect, but the price is relatively high and is generally used in high-end hangars.

2. Characteristics of sandwich panels

- Thermal insulation: Sandwich panels have good thermal insulation properties, which can effectively reduce temperature fluctuations in the hangar and improve indoor comfort.

- Sound insulation and noise reduction: The sound insulation effect of sandwich panels helps reduce noise in the hangar and improve the working environment.

- Easy installation: Sandwich panels are light in weight, high in strength, easy to transport and install, and can improve construction efficiency.

- Energy saving and environmental protection: Sandwich panels are generally made of environmentally friendly materials, which have good energy saving effects and meet the requirements of green buildings.

3. Application of roofing sandwich panels in prefab hangar

In prefab hangar roofing, sandwich panels are used as the main structural material, and their performance directly affects the overall quality and service life of the hangar. Therefore, when selecting sandwich panels, comprehensive considerations need to be taken into consideration based on factors such as the hangar’s usage needs, geographical location, and climatic conditions. For example, for hangars in cold areas, rock wool sandwich panels or PU sandwich panels with better thermal insulation performance should be used; while for warm areas, EPS sandwich panels have a higher cost performance. At the same time, considering the noise problem in the hangar, rock wool sandwich panels and PU sandwich panels have better sound insulation effects and can be selected according to actual needs.

During the installation process, attention should be paid to the arrangement sequence, connection method and fixation method of the sandwich panels to ensure the stability, sealing and waterproofing of the roof. In addition, in order to extend the service life of the hangar, regular roof inspection, maintenance and upkeep are also essential.

In summary, choosing the right roofing sandwich panels is crucial when building the prefab hangar. Various types of sandwich panels have different characteristics in terms of thermal insulation, sound insulation, and ease of installation, and should be selected according to actual needs. At the same time, attention should be paid to installation quality and subsequent maintenance during the construction process to ensure the safety, stability and long-life operation of the prefabricated hangar.