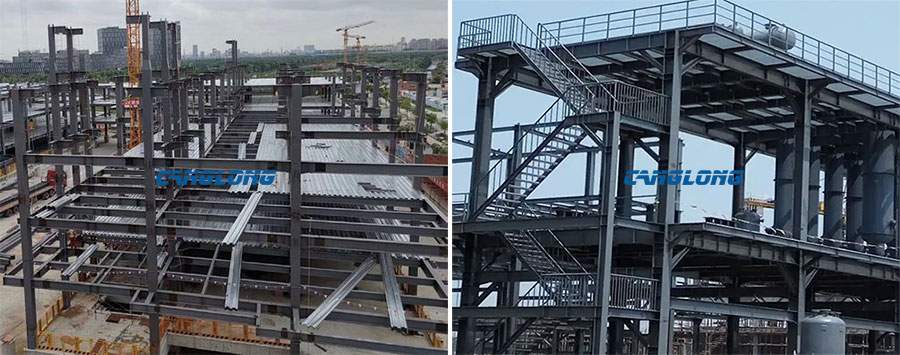

Multi Storey Steel Structure

- High material strength and light weight

- Steel toughness, good plasticity, uniform material and high structural reliability

- High degree of mechanization of steel structure manufacturing and installation

- Good sealing performance of steel structure

- Steel structure is heat-resistant and not fire-resistant

- Poor corrosion resistance of steel structure

- Low carbon, energy saving, green and environmental protection, reusable

Product Detail

Steel structure is a structure composed of steel materials and is one of the main types of building structures. The multi-layer steel structure is mainly composed of steel beams, steel columns, steel trusses and other components made of section steel and steel plates, and adopts rust removal and rust prevention processes such as silanization, pure manganese phosphating, washing and drying, and galvanizing. Welds, bolts or rivets are usually used to connect components or parts. Because of its light weight and simple construction, multi-layer steel structures are widely used in large workshops, stadiums, super high-rises and other fields. The multi-layer steel structure is easy to rust. Generally, the steel structure needs to be derusted, galvanized or painted, and it needs to be regularly maintained.

Features of steel structure:

1. High material strength and light weight

Steel has high strength and high modulus of elasticity. Compared with concrete and wood, the ratio of its density to yield strength is relatively low, so under the same stress conditions, the steel structure has a small cross-section and light weight, which is convenient for transportation and installation, and is suitable for large spans, high heights, and heavy loads Structure.

2. Steel toughness, good plasticity, uniform material and high structural reliability

The multi-layer steel structure is suitable for bearing shock and dynamic loads and has good seismic performance. The internal structure of steel is uniform, close to isotropic homogeneous body. The actual working performance of the steel structure is more in line with the calculation theory. Therefore, the reliability of the steel structure is high.

3. High degree of mechanization of steel structure manufacturing and installation

Steel structural members are easy to manufacture in factories and assemble on site. The factory mechanized manufacturing of multi-layer steel structural components has high finished product precision, high production efficiency, fast assembly speed on site, and short construction period. Steel structure is the most industrialized structure.

4. Good sealing performance of steel structure

Because the steel structure welding can be completely sealed, it can be made into high-pressure containers, large oil pools, pressure pipes, etc. with good air-tightness and water-tightness.

5. Steel structure is heat-resistant and not fire-resistant

When the temperature is below 150 °C, the properties of the steel change little. Therefore, the steel structure is suitable for hot workshops, but when the surface of the structure is exposed to heat radiation of about 150 ° C, it should be protected by a heat insulation board. When the temperature is between 300°C and 400°C, the strength and elastic modulus of the steel decrease significantly. When the temperature is around 600°C, the strength of the steel tends to zero. In buildings with special fire protection requirements, the steel structure must be protected by refractory materials to improve the fire resistance rating.

6. Poor corrosion resistance of steel structure

Especially in the environment of wet and corrosive media, the steel structure is easy to rust. Generally, high-rise steel structures should be derusted, galvanized or painted, and should be regularly maintained. For the structure of the offshore platform in seawater, special measures such as “zinc block anode protection” should be adopted to prevent corrosion.

7. Low carbon, energy saving, green and environmental protection, reusable

The demolition of steel structure buildings hardly produces construction waste, and the steel can be recycled and reused.

Multi storey steel structure installation:

- The prefabrication and assembly of steel components are carried out on the steel platform according to the installation sequence and process requirements, and the welding quality must be guaranteed.

- The distance between the splicing flange plate splicing seam and the web splicing seam of the profiled steel should be greater than 200mm. The splicing length of flange plates should not be less than 2 times the plate width, the splicing width of web plates should not be less than 300mm, and the length should not be less than 600mm.

- In order to facilitate the welding and ensure the welding quality, try to make butt welding on the steel platform on the ground according to the size of the construction drawing, as far as possible, the stiffener plates, connecting plates, backing plates, and beams (beams) on the columns and beams.

- In addition to the fabrication and assembly of prefabricated steel components on the steel platform according to the construction drawings and specifications, the manufacturability of on-site installation and changes in installation dimensions should also be considered.

High-rise steel structure construction technology

Connection method: welding connection, bolt connection, rivet connection.

Preparations for steel structure installation and welding

1. Welding materials and equipment for manual arc welding and CO2 gas shielded welding.

2. Installation and welding procedures and general regulations.

3. Welding sequence and process parameters of typical nodes.

4. Column-beam, beam-beam joint.