Steel Structure Warehouse

| PRODUCT PARAMETER | |

|---|---|

| Place of Origin: | Henan, China (Mainland) |

| Standard: | GB Standard, EU Standard, ASTM Standard, BS Standard, AS/NZS Standard |

| Certificates: | CE, ISO9001 |

| Grade: | Q235 / Q355 |

| Type: | Light Steel Structure |

| Surface Treatment: | Painted & Hot dip galvanized |

| Columns and Beams: | H-section Steel |

| Purlin: | C.Z Shape Steel Channel |

| Roof and Wall Panel: | Sandwich Panel, Color Steel Sheet |

Product Detail

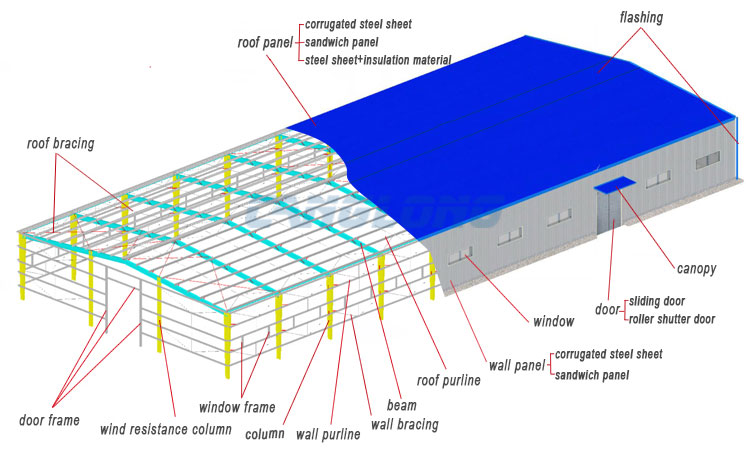

The steel structure warehouse is mainly composed of steel columns, steel beams, steel frames, wall panels, roof panels and rigid supports. All steel structural members are manufactured in the workshop and transported to the project site. They are installed quickly, green building and labor saving.

The steel frame warehouse can meet a wide range of project needs – from commerce (shed, exhibition hall) to agriculture (metal warehouse, warehouse shed) to industry (workshop, equipment warehouse). All components are prefabricated and can be installed directly without field cutting and drilling, saving installation time and labor cost.

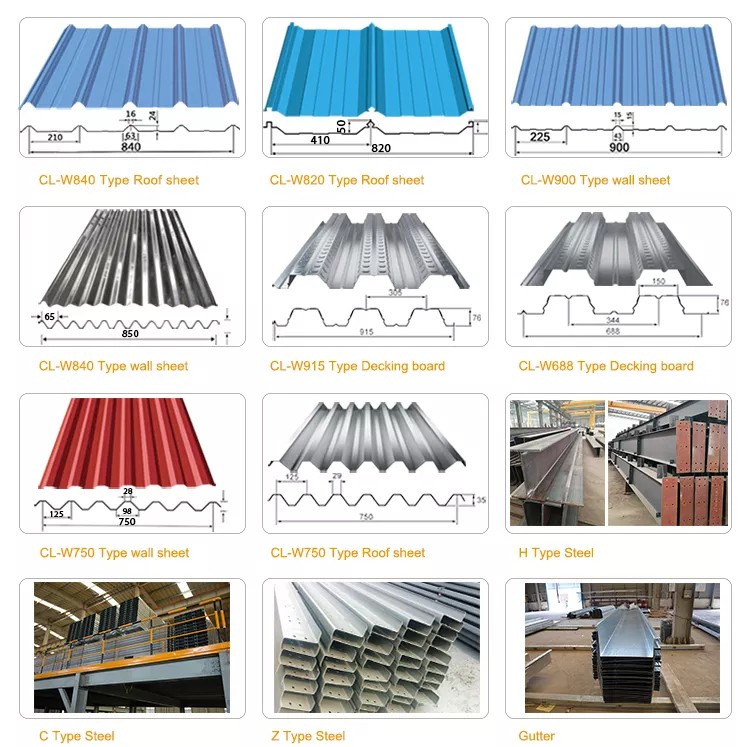

Steel structure warehouse roof and wall materials

Steel structure panel materials include PU sandwich panel, EPS sandwich panel, fiberglass, rock wool sandwich panel, and color steel sheet.

Sandwich material: EPS, PU, rock wool, glass wool

Sandwich panel thickness: 50mm, 75mm, 100mm, 150mm, 200mm

Monochrome plate material thickness: 0.2-0.8mm

Advantages of steel structure warehouse

1. Easy installation: Fast and flexible assembly, safe, heat insulation, sound insulation, waterproof, fireproof.

2. Low cost: The quick and easy installation greatly shortens the construction time and reduces the cost.

3. Durability: The overall structure is easy to maintain and has a service life of more than 50 years.

4. Perfect design: Perfect design completely avoids leakage and water seepage. At the same time, it also complies with international fire protection standards.

5. Bearing capacity: It can resist the influence of strong wind and earthquake, and withstand heavy snow.

The combination of light steel building structures in construction engineering, railway, petrochemical industry, water conservancy construction, highway construction and military engineering, as well as earthquake and disaster relief in temporary fields are widely used in construction.

Estimated cost of building steel structure warehouse

| Building Type | Cost per square foot | Basic cost of 10,000 square foot | Total cost(including accessories) |

| Prefabricated warehouse kits | $3.40 to $5.20 | $34,000 to $52,000 | $45,790 to $63,410 |

| Rigid-frame warehouse | $5.00 to $10.00 | $50,000 to $100,000 | $64,800 to $117,300 |

| Warehouse packages | $6.50 to $12.00 | $65,000 to $120,000 | $72,500 to $131,800 |

| Finished and enclosed warehouse | $8.60 to $15.00 | $86,000 to $150,000 | $93,600 to $162,500 |

The steel structure warehouse building has the advantage of diversity and can meet the needs of different projects. It can be used as car shed and exhibition hall in commercial buildings. It can be used as metal silos and farmhouses in agricultural buildings. It can be used as a workshop in industrial buildings.

We designed the prefabricated warehouse to maximize the use of internal space. There are free columns in the metal warehouse. Forklifts can be used freely to improve the utilization rate of the warehouse. The prefabricated steel structure warehouse is durable, can resist rain, snow, wind and other bad weather, and has excellent seismic resistance. And the wall and roof cladding is coated with aluminum compound to prevent rust and prolong service life.

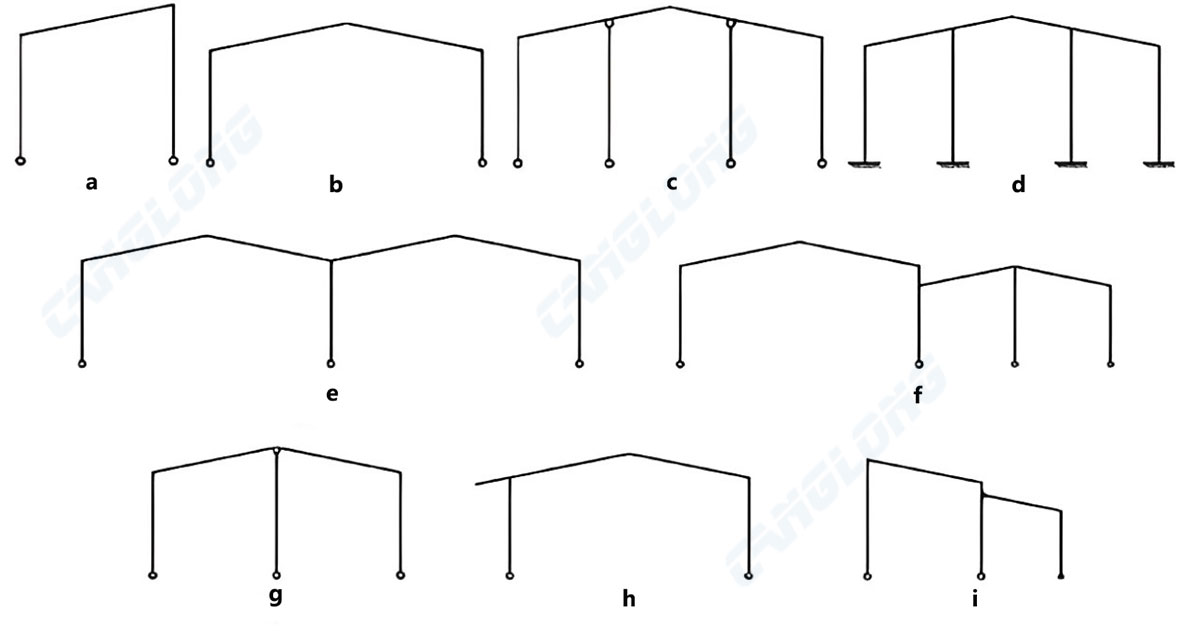

Type of Roof Frame Structure

Main Components For Steel Structure Warehouse

| Name | Steel structure warehouse | |

| H beam Dimensions |

Length | 4000-15000mm |

| Thickness | web plate: 6-32mm wing plate: 6-40mm |

|

| Height | 200-1200mm | |

| Color | According to customers | |

| Warehouse Size | Width * length * eave height | |

| Advantages | 1. Lower cost with better quality. 2. High safety performance. 3. Easy to assemble and dismantle. 4. Manufacture under complete quality control system – ISO9001. 5. Installation with instruction of experienced engineers 6. Non-pollution. |

|

| Main components | Base | Cement and steel foundation bolts |

| Main frame | H beam | |

| Material | Q235B, Q345B or others as buyers’ requests. | |

| Purlin | C or Z purlin: Size from C120~C320, Z100~Z20 | |

| Bracing | X-type or other type bracing made from angle, round pipe | |

| Bolt | Plain bolt and High-strenth bolt | |

| Roof & wall | Sandwich panel or color plate | |

| Door | Sliding or rolling door | |

| Window | Aluminium alloy window | |

| Surface | Two lays of Anti-rust Painting or Hot Dip Galvanized | |

| Sheet | 0.5mm or 0.6mm galvanized sheet | |

| Accessories | Semi-transparent skylight belts, Ventilators,down pipe, Glavanized gutter, etc | |

| Usages | 1. workshop, warehouse, plant 2. Steel web frame structure 3. Steel H-column and steel H-beam 4. Portal frame products 5. High rise building project 6. Others steel structure buildings |

|

| Packing | Main steel frame without packing load in 40′ OT; Roof and wall panel load in 40′ HQ! |

|

| Drawing | According to drawings or customers’ requirements. | |

| Design Parameters | If you need we design for you, please supply us the following parameter together with detail size: 1. length, width, height, eave height, roof pitch, etc 2. wind load, snow load, raining condition, aseismatic requirements, etc 4. Demands for doors and windows 5. Other information if necessary |

|

Industrial Steel Structure Warehouse Design and Modeling

Transportation

Usually after customer orders, our engineering department will design the shipment according to the internal dimensions of 40’HQ and 40′ open top container with steel structure. In most cases, we use 40’HQ and 40′ open top shipping containers to pack steel structures.

Application display of steel structure warehouse

Customer project display

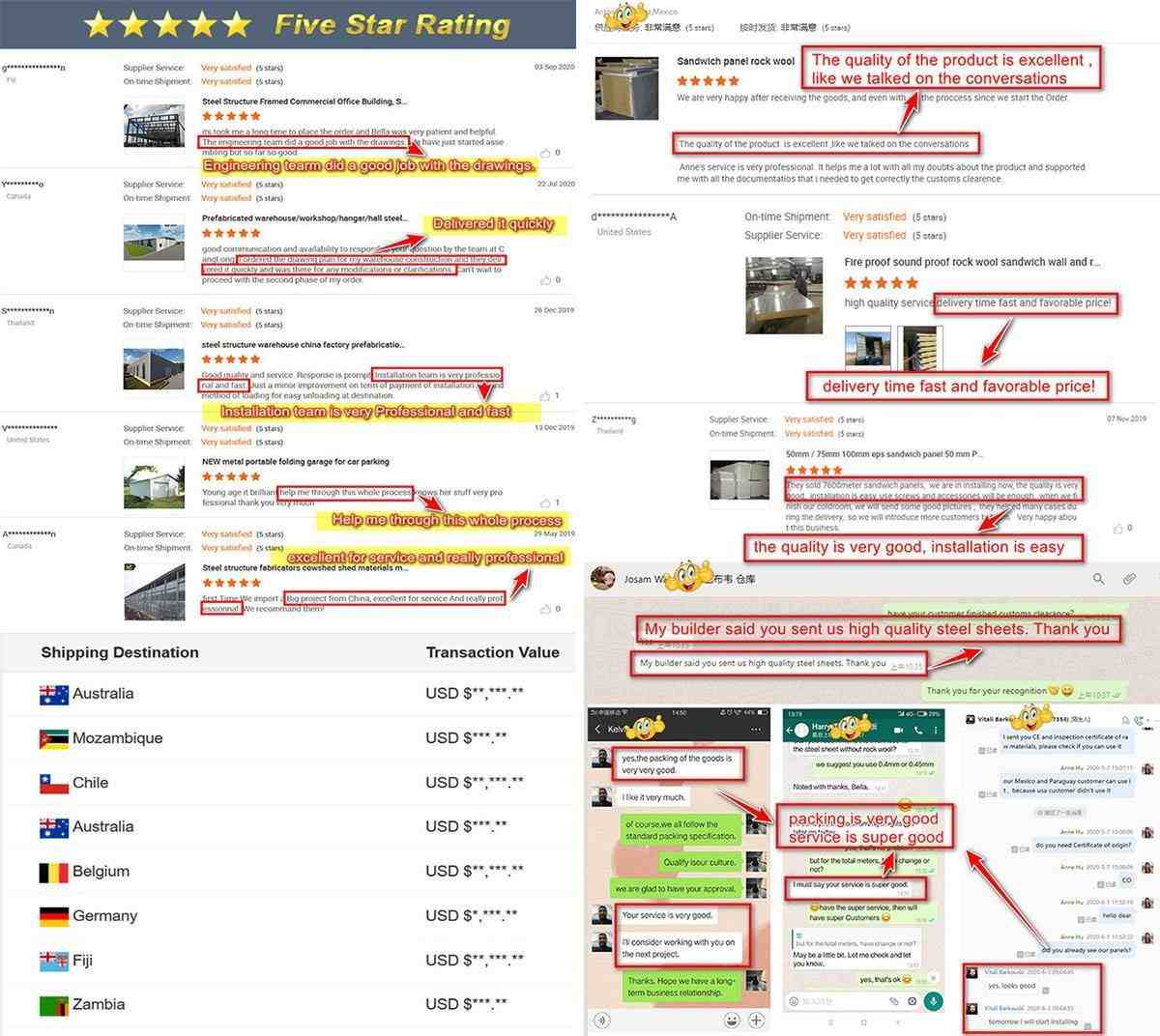

Customer evaluation