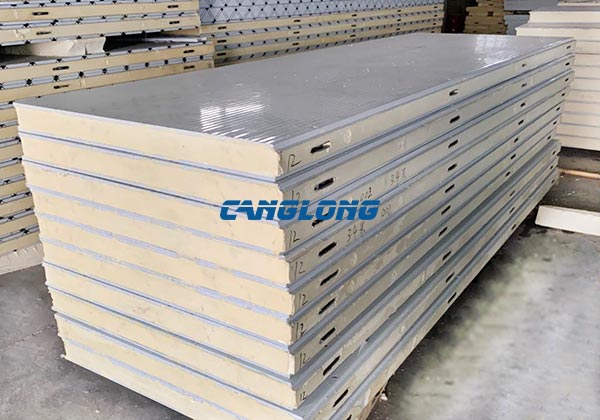

Cold Storage Board

| PRODUCT PARAMETER | |

|---|---|

| Place of Origin: | Henan, China (Mainland) |

| Standard: | GB Standard |

| Certificates: | CE, ISO9001 |

| Brand Name: | Canglong Group |

| Surface Treatment: | Painted & Hot dip galvanized |

| Metal sheet: | steel sheet / Aluminum plate |

| Metal sheet thickness: | 0.4~0.8mm |

| Core Material: | polyurethane |

| Core Material Thickness: | 50/75/80/100/120/150/200mm |

| Width: | 1000/1120mm, 960/1150mm |

Product Detail

Cold storage board is generally pre produced by the manufacturer, with fixed length, width and thickness. High and medium temperature cold storages generally use 10cm thick plates, while low temperature storages and freezing storages generally use 12cm or 15cm thick plates. Therefore, if it is not the predetermined warehouse board, pay attention to the density of the warehouse panel and the thickness of the steel plate when purchasing. The thickness of the steel plate of regular manufacturers is generally more than 0.4mm, and the foaming density of the cold room panel is 38kg ~ 40kg / m3 per cubic meter according to the national standard.

Polyurethane cold storage board

Polyurethane cold storage board takes light polyurethane as the inner material of the cold storage panel. The advantage of polyurethane is that the thermal insulation performance is very good. The exterior of polyurethane cold room panels are composed of SII, PVC color steel sheet and stainless steel plate. The advantage of this is to prevent the temperature transmission of the cold storage sandwich panel due to the large internal and external temperature difference, so as to make the cold storage more energy-saving and improve the working efficiency of the cold storage.

Selection of cold storage board

The selection of polyurethane cold storage board is very important for cold storage, because cold storage is different from other warehouses. Cold storage has high environmental requirements such as temperature and humidity. Therefore, when selecting the cold storage wall panel, we should pay attention to the material and thermal insulation strength of the panel, and select the correct board to better maintain the cold storage. Cold room panels mainly uses polyurethane and polyurethane as raw materials. In addition, there are also polyurethane sandwich panel with the best performance. The density of thermal insulation materials foamed by polyurethane is thin and not enough for thermal insulation. They are generally used in special equipment. Polyurethane is a good raw material. After a certain ratio, it can foam thermal insulation materials with appropriate density, good thermal insulation effect and high load-bearing capacity. Polyurethane sandwich panel is the best, with the best thermal insulation performance and no moisture absorption, but the price is slightly higher.

Characteristics of cold storage board

The cold storage board has the characteristics of corrosion resistance, aging resistance, flame retardant, non-toxic, light and cheap, solid and pressure resistant, safe and reliable, beautiful appearance, convenient operation, long service life and sanitation.

Specification of polyurethane panel

The thickness specifications of polyurethane cold room panel generally include: 50, 60, 75, 100, 120, 150, 180 and 200mm. The standard width of the cold storage panel is 960mm and the height is generally between 2-10M. Of course, if the user has special requirements, it can also be customized. This size is not absolute.

Types of cold storage boards

Cold storage boards are generally classified according to materials, and the most commonly used materials are polyethylene and polyphenylene. In addition to these two materials, there are polyurethane sandwich panels with very good performance. Polyphenylene cold storage panels are generally used in special equipment because the density of thermal insulation materials is relatively thin and not enough for thermal insulation, while polyethylene is better and the thermal insulation effect is relatively high. Of course, the best is polyurethane cold storage board. Of course, the price is relatively high. However, polyurethane cold room panel has won a very wide application in the cold storage industry with its excellent thermal insulation performance.

Protective material

The protective materials of cold storage panel mainly include: embossed aluminum plate, stainless steel plate, color zinc steel plate, salted steel plate and standard platform plate. We usually use more embossed aluminum plate and stainless steel plate.

Parameters of sandwich panel