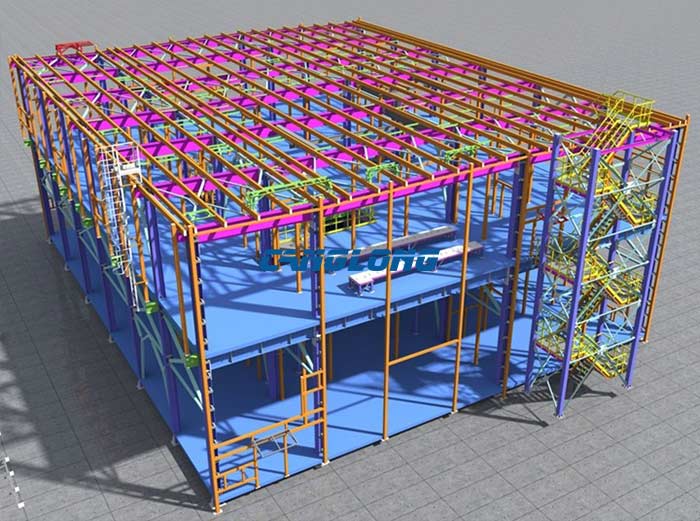

Double Storey Steel Workshop

| PRODUCT PARAMETER | |

|---|---|

| Place of Origin: | Henan, China (Mainland) |

| Standard: | GB Standard |

| Certificates: | CE, ISO9001 |

| Grade: | Q235 / Q355 |

| Brand Name: | Canglong Group |

| Type: | Light Steel Structure |

| Surface Treatment: | Painted & Hot dip galvanized |

| Columns and Beams: | H-section Steel |

| Purlin: | C.Z Shape Steel Channel |

| Roof and Wall Panel: | Sandwich Panel, Color Steel Sheet |

Product Detail

In the plane layout of the double layer steel workshop, in order to meet the process requirements, the structural layout is irregular, the column network is irregular, the beam layout is irregular, and even the process requirements require the opening on the main stressed components. At the same time, the internal space of the plant is generally large, and the column spacing is mostly 6~12m. If there is a column pulling design locally, the column spacing will increase to more than 18m. This makes the force transmission of the structure complex, the force is not clear, and the stress concentration phenomenon is easy to occur in the design.

Vertical structure layout and floor height

The storey height of the multi storey steel structure workshop is large, which can reach 4~8m, and the vertical layout often has staggered floors, mezzanine, and large holes in the floor, which makes the floor unable to provide sufficient in-plane stiffness, and the effective mass of the structure is unevenly distributed along the vertical. Under seismic action, the structure may produce “short column effect”, which makes the horizontal shear force of local column section become the control factor of section design.

Various types of loads

The concentrated load of the steel structure workshop mainly includes the dead weight of the equipment, and sometimes the vibration disturbance of the equipment needs to be considered for dynamic calculation according to the requirements of the specification. Suspension load mainly includes pipeline load, crane load, and sometimes horizontal load and bending moment are generated by the pipeline. According to the requirements of production process, the plate surface load has different values of live load on the ground of different production buildings, but this kind of live load is generally greater than the live load in civil buildings.

Floor and foundation form

The floor of multi storey steel structure workshop generally adopts steel plate floor. The foundation form of the double layer steel workshop mostly adopts the independent foundation under the column, and the strip foundation under the column. If the foundation bearing capacity is low, the lime soil compaction pile, sand pile and other methods can be used for treatment, or the cast-in-place pile can be used to directly act on the hard soil layer.

Light enclosure

The enclosure structure of the double layer steel factory building is generally not used as a load-bearing system, and light-weight materials are usually used. The roof structure mostly adopts the steel truss purlin system with light-weight insulation layer. This light enclosure material is beneficial to reduce the dead weight of the structure and reduce the seismic response.

Problems needing attention in structural design of multistory steel structure workshop

The structural forms and loads between multi-storey steel structure buildings and multi-storey and high-rise civil buildings have their own characteristics. It has large span, high floor height, thick floor, few internal partitions and crane load. Some problems need to be paid attention to when using the software for spatial analysis.

Plane and vertical layout rules

To avoid sudden change, multistory structure workshop building generally adopt frame structure system because of the requirements of process layout and large space span. The structure should be arranged so that the column grid is uniform and symmetrical. In order to reduce the spatial torsion of the house, the stiffness center of the house should be close to the mass center. The structural system shall be as regular and simple as possible, and the force transmission shall be clear. When setting the structural system, attention shall be paid to prevent the contraction, concave angle and stress concentration of sudden deformation. The vertical change shall not be too inward or outward, and the vertical stiffness shall be less abrupt or even not abrupt.

Reasonably arrange the support system

When the earthquake intensity is high and the equipment load is large, in order to reduce the impact of horizontal load on the steel structure, control the structural displacement, optimize the column section, and coordinate the process to arrange the support system of the structure. Bracing can reduce the calculated length of structural members, increase stability, enhance the overall stability and spatial stiffness of multistory structure workshop, and transfer some horizontal loads to the main load-bearing members such as columns.

The horizontal and vertical cycles of the frame should be controlled to be similar

As the span and size of multi-storey plants are not small, there are not many columns. However, the dimension of column spacing direction is very small, and there are many columns. Under normal circumstances, the horizontal control method is adopted to make the seismic capacity between the horizontal and vertical basically equal. The design is not only scientific and reasonable, but also ensures the seismic effect.

Approximate calculation of multi-storey crane

The multi-storey factory buildings are equipped with multi-storey and multiple cranes. With the current technology, we cannot calculate the multi-storey cranes through the calculation software, which must be compensated in the design link. In the design, the crane on the first floor is input as the crane load, and the crane load on the other floors is considered as the live load.

Set up reasonable destruction mechanism

Earthquake and other geological disasters will cause different degrees of damage to the structure, and the degree of loss depends on the degree of damage. Therefore, it is the main work of structural engineers to optimize the damage order and prevent more serious losses caused by the deepening of the damage. In this specification, engineers should grasp a working principle: to avoid the damage of the whole structure before the structural part. The main work contents include:

- 1. Strong column and weak beam, that is to avoid the damage of column before the damage of beam. The key to the firmness of the whole structure is whether the column is firm.

- 2. Strong joints and weak bars, to avoid the damage of the joint structure before the damage of the members, and the joints are closely related to most of the members, so it is necessary to ensure that the joints are intact.

- 3. Strong shear and weak bending, the shear failure occurs suddenly and cannot be accurately predicted in advance. However, the bending failure has a curve change, which can often predict the danger in advance, which can effectively prevent the further spread of the failure.

Handling of non structural components

Non structural components refer to non main load-bearing and load-bearing components such as partition wall, enclosure wall and parapet. Although they are not part of the main structure, they can change the stress state and distribution law of the main structure components during the earthquake. Therefore, the treatment of non structural components is of great significance for the overall seismic capacity of building structures.

Therefore, first of all, let the non structural components become a part of the seismic structure as a whole or let the non structural components have no relationship with the seismic structure as a whole. Secondly, the connection between ornaments and the whole structure should be reliable. Thirdly, the partition wall and enclosure wall should avoid the adverse impact on the structural earthquake resistance, the vertical connection should be uniform, and the distribution on the plane should be uniform and symmetrical.

Advantages of using steel structure in multi-storey plants:

- 1. The material has high strength and light weight, which is convenient for transportation and installation.

- 2. The steel has good toughness and plasticity, uniform material and high structural reliability.

- 3. The steel structure manufacturing and installation is highly mechanized, which is easy to manufacture in the factory and assemble on the site.

- 4. The steel structure has good sealing performance, and can be made into high-pressure vessels with good air tightness and water tightness, large oil pools, pressure pipelines, etc.

Disadvantages of steel structure:

- 1. the steel structure is not fire-resistant. When the temperature is 300 ℃ ~400 ℃, the steel strength and elastic modulus decrease significantly. When the temperature is about 600 ℃, the steel strength tends to zero. In buildings with special fire protection requirements, steel structures must be protected with refractory materials to improve the fire resistance rating.

- 2. the steel structure has poor corrosion resistance, especially in the environment of wet and corrosive medium, it is easy to rust. General steel structures shall be derusted, galvanized or coated, and shall be maintained regularly.