Steel Warehouse Building

| PRODUCT PARAMETER | |

|---|---|

| Place of Origin: | Henan, China (Mainland) |

| Standard: | EU Standard, ASTM Standard, BS Standard, AS/NZS Standard |

| Certificates: | CE, ISO9001 |

| Grade: | Q235 / Q355 |

| Type: | Light Steel Structure |

| Surface Treatment: | Painted & Hot dip galvanized |

| Columns and Beams: | H-section Steel |

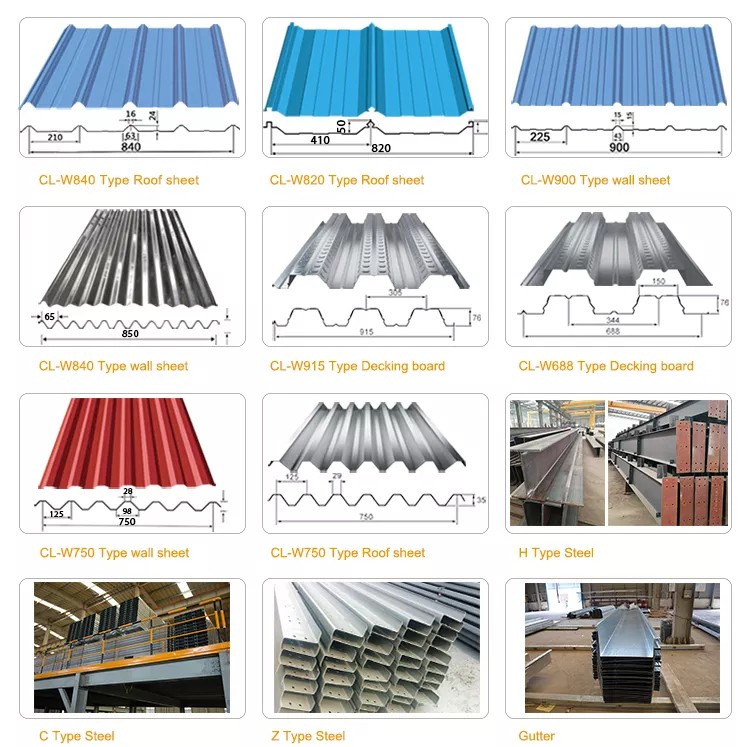

| Purlin: | C.Z Shape Steel Channel |

| Roof and Wall Panel: | Sandwich Panel, Color Steel Sheet |

Product Detail

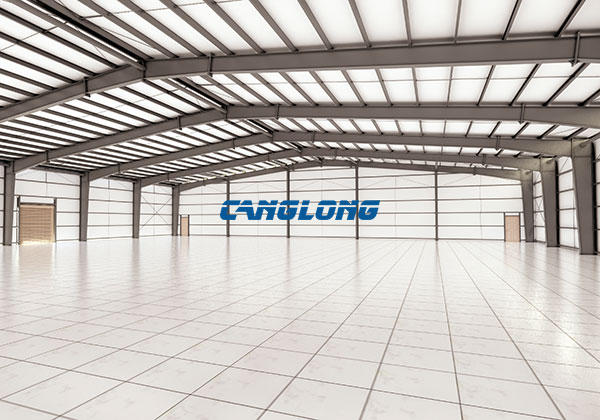

The parts of the steel warehouse building are all prefabricated in the factory, and the products are directly transported to the construction site, only need to lift and connect. The construction is also very fast, which can meet the urgent warehouse construction needs of some factories. In the construction cycle, steel warehouses have obvious advantages.

The steel structure warehouse building can be operated without water through dry construction, only fine dust is generated, and the pollution to the environment and the impact on the nearby residents are reduced. Currently concrete buildings cannot do this. The environmental protection advantages of steel structure warehouses are obvious.

The steel structure has a heavy weight, and the walls and roof of the steel structure are made of lightweight metal building materials, which are much lighter than brick walls and doba roofs, which can reduce the overall weight of the warehouse without compromising the stability of the structure.

The steel structure warehouse combines this selling point, and the warehouse built with this material structure uses a larger area. Warehouses generally store items, and we are most afraid of some objective factors that affect the goods stored in the warehouse, such as fire and corrosion. The steel structure warehouse largely avoids these problems. First of all, buildings constructed with steel structures are lighter and relatively lighter in strength. In addition, the general large-scale warehouse has a large span, and the steel structure just meets the conditions.

There are many warehouse needs are more urgent, especially large warehouses. The biggest advantage of choosing a steel warehouse building is that the construction period of the steel structure is shorter, the construction is more convenient, and the investment cost is greatly reduced.

In addition, with the development of business, some people’s warehouses will inevitably face the problem of moving addresses, and another advantage of steel structure buildings is highlighted at this time. Because the steel structure warehouse is lighter, it will be more convenient to move the project, and the recycling is pollution-free. In an era when the environment is so bad and the air pollution is relatively serious, after the steel warehouse building is used, it will no longer be used, and the waste can be recycled without pollution.

As a basic storage facility, a warehouse can be classified according to its role or characteristics in the flow of goods. However, no matter how it is divided, its essential function is to store. In response to the different needs of the market for warehouse buildings. In recent years, more and more prefabricated steel structure warehouses have appeared on the market, which has caused many entrepreneurs to abandon the reinforced concrete structure building model that has been used for many years.

Advantages of Steel Warehouse Buildings

- The construction speed of the steel warehouse is fast, and the emergency advantage is obvious, which can meet the sudden storage needs of enterprises.

- The steel structure warehouse adopts dry construction, which has outstanding environmental protection advantages. Compared with the wet construction of reinforced concrete buildings, the impact of engineering construction on the environment and nearby residents can be reduced.

- Prefabricated steel warehouse buildings save on construction costs and labor costs compared to traditional concrete warehouses. The cost of building a steel structure warehouse is 20%~30% lower than that of a traditional warehouse, and it is safer and more stable.

- The steel structure is lightweight. The building materials used for the walls and roofs are much lighter than brick-concrete walls and terracotta roofs, effectively reducing the overall weight of the steel structure warehouse without compromising its structural stability. It can also reduce the transportation cost of components brought by relocation and save costs.

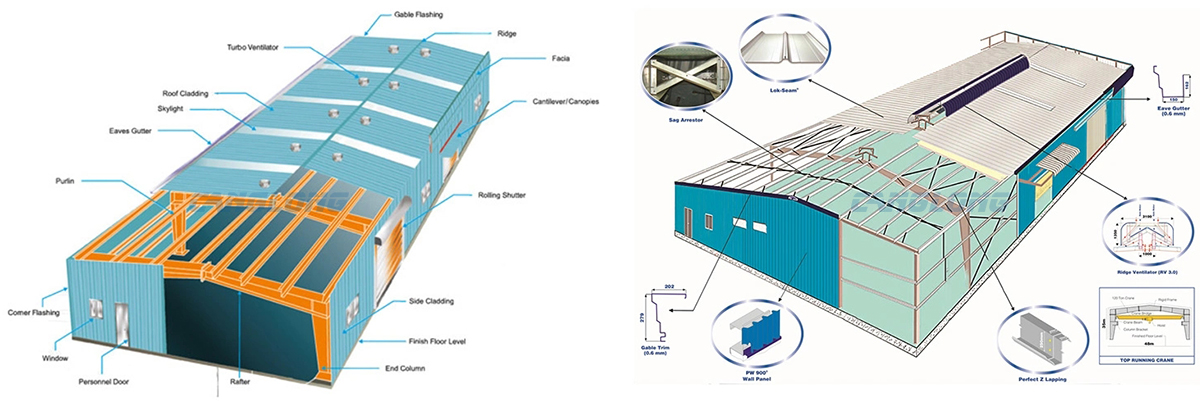

Main Components For Steel Warehouse Building

| Items | Specification | |

| Main Steel Frame | Column | Q235, Q345 Welded H Section Steel |

| Beam | Q235, Q345 Welded H Section Steel | |

| Secondary Frame | Purlin | Q235 C and Z purlin |

| Knee brace | Q235 Angle Steel | |

| Tie Rod | Q235 Circular Steel Pipe | |

| Brace | Q235 Round Bar | |

| Vertical and Horizontal Support | Q235 Angle Steel, Round Bar or Steel Pipe | |

| Maintenance system | Roof Panel | EPS Sandwich Panel /Glass Fiber Sandwich Panel / Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet |

| Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

| Accessories | Window | Aluminium Alloy Window / PVC Window / Sandwich Panel Window |

| Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

| Downspout | PVC | |

| Live load on Roof | In 120kg/Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | 12 Grades | |

| Earthquake-resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Temperature | Suitable temperature.-50ºC~+50ºC | |

| Certification | CE, SGS, ISO9001:2008, ISO14001:2004 | |

| Finishing Options | Vast array of colors and textures available | |

| Paint Options | Alkyd painting, two primary painting, two finish painting (gray paint, red paint, white paint, epoxy zinc etc.) Or Galvanized. |

|

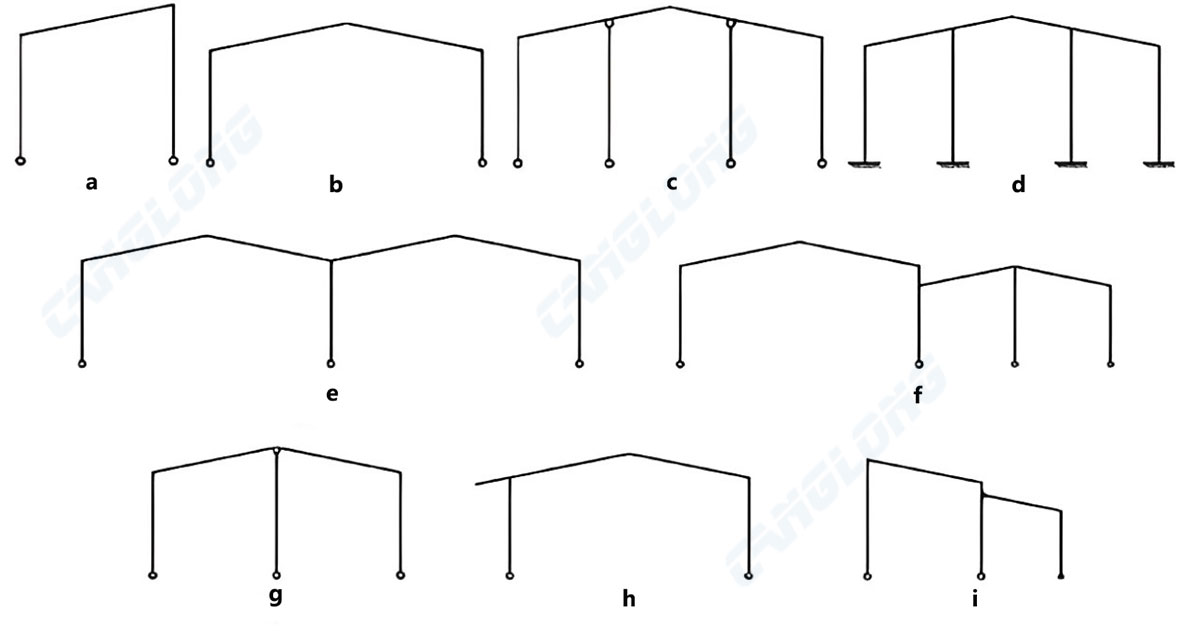

Type of roof structure