Innovative application of insulated sandwich panels in cold chain logistics

With the rapid development of modern cold chain logistics, the demand for insulation materials is increasing day by day. Traditional insulation materials are no longer able to meet the requirements of high efficiency, energy conservation, environmental protection, and other aspects. In this context, insulated sandwich panels, as a new type of insulation material, have shown great potential for innovative applications in cold chain logistics.

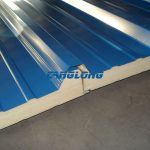

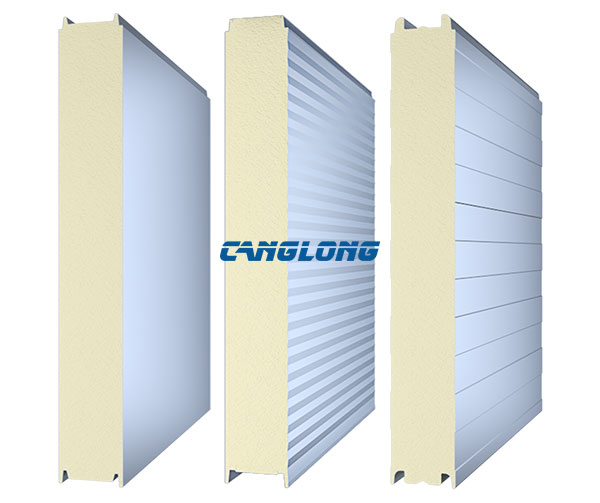

Thermal insulation sandwich board is usually composed of two layers of metal plates (such as color steel plate or glass steel plate) and thermal insulation materials filled in the middle (such as polyurethane, polystyrene foam, etc.). This structure not only ensures the high strength of the sandwich panel, but also endows it with excellent thermal insulation performance. In cold chain logistics, insulated sandwich panels are widely used in various links such as cold storage, refrigerated trucks, and refrigerated containers, effectively reducing energy consumption and extending the shelf life of perishable goods.

1. Excellent thermal insulation performance

The core advantage of insulated sandwich panels lies in their excellent thermal insulation performance. Taking polyurethane insulation sandwich panel (PU) as an example, this material uses polyurethane foam as the insulation layer, which has an extremely low thermal conductivity, can significantly reduce the heat transfer inside the cold storage and reduce energy consumption. Compared with traditional polyurethane composite panels, PUF sandwich panels require a smaller thickness, lighter weight, and more convenient installation while maintaining the same insulation effect.

2. Widely applicable scenarios

In cold chain logistics, insulation sandwich panels have a wide range of application scenarios. From large cold storage to small refrigerated trucks, from refrigerated containers to commercial refrigerators, insulated sandwich panels can all leverage their unique advantages. For example, in cold storage construction, PU sandwich panels can be used as insulation materials for walls, roofs, and floors, which not only improves the insulation performance of the cold storage, but also beautifies the appearance of the cold storage, making it easy to clean and maintain. In the field of refrigerated trucks, the application of insulated sandwich panels can effectively maintain a low temperature environment inside the compartment, ensuring that the goods are not affected by temperature fluctuations during transportation.

3. Dual advantages of environmental protection and energy conservation

With the global emphasis on environmental protection and energy conservation, the application of insulation sandwich panels in cold chain logistics is also paying more attention to environmental protection and energy conservation. Polyurethane insulation sandwich panel production enterprises represented by Huntsman have reduced the carbon footprint of their products by using environmentally friendly materials such as recycled polyester polyols. At the same time, polyurethane insulated sandwich panels also have excellent thermal insulation performance, which can significantly reduce the energy consumption of cold chain facilities such as cold storage, and help reduce carbon emissions in the cold chain industry.

4. The Future of Innovation and Development

Looking ahead to the future, the application of insulated sandwich panel in cold chain logistics will continue to innovate and develop. With the advancement of technology and the increasing demand from consumers, insulation sandwich panels will continue to be upgraded in terms of material properties, structural design, and intelligent applications. For example, by introducing new nanomaterials such as graphene, the thermal conductivity and mechanical properties of insulation sandwich panel can be further improved; Through intelligent control systems, remote monitoring and automatic adjustment of cold chain logistics facilities can be achieved, improving management efficiency and energy-saving effects.

In summary, as a key insulation material in cold chain logistics, insulated sandwich panels are contributing significantly to the sustainable development of the cold chain industry due to their excellent performance, wide application scenarios, and dual advantages of environmental protection and energy conservation. With the continuous advancement of technology and the continuous expansion of the market, the application prospects of insulation sandwich panels in cold chain logistics will be even broader.