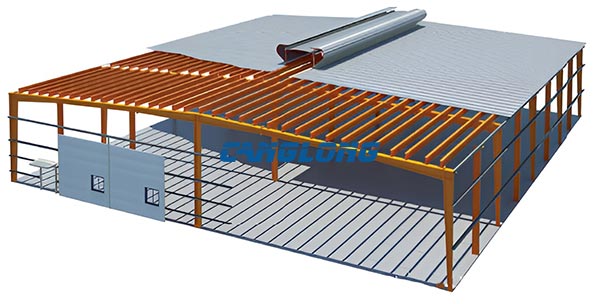

Prefabricated workshop building design advantages and application scenarios

In the modern construction industry, prefabricated workshop building is gradually emerging. With their unique design advantages and wide application scenarios, they provide efficient and flexible space solutions for various industrial production.

Design advantages

Efficient construction: The components of prefabricated workshop buildings are pre-produced in the factory and only need to be assembled on site, which greatly shortens the construction period. Compared with the traditional on-site pouring construction method, it can save a lot of time and cost. Taking a medium-sized prefabricated workshop as an example, its construction time may be only half of that of traditional buildings or even shorter, which enables enterprises to put into production operations faster and seize market opportunities.

Controllable quality: In a factory production environment, the production process of components is subject to strict quality control. From the screening of raw materials to the execution of production processes, there are standardized processes to ensure the dimensional accuracy and performance quality of each component. Compared with on-site construction, which is easily affected by factors such as weather and workers’ technical level, the quality of prefabricated workshop building is more stable and reliable, reducing the cost of later maintenance and rectification.

High flexibility: Prefabricated components can be customized according to different design requirements, whether it is the span, height or internal layout of the workshop, it can be flexibly adjusted. This flexibility enables prefabricated workshop buildings to adapt to various types of production needs, whether it is light manufacturing or heavy industry, you can find a suitable prefab workshop solution. At the same time, when the workshop needs to be renovated or expanded in the future, the detachable and reconfigurable characteristics of prefabricated buildings can also provide great convenience.

Energy saving and environmental protection: Prefabricated workshop building reduce on-site wet operations during the production process and reduce the amount of construction waste. At the same time, due to the precise production of components, material waste is reduced. Moreover, prefabricated buildings usually use efficient thermal insulation materials, which improves the energy utilization efficiency of buildings and reduces energy consumption during operation, which is in line with the current development trend of energy conservation and environmental protection.

Application scenarios

Manufacturing: Manufacturing is one of the main application areas of prefabricated workshop buildings. For industries such as automobile manufacturing and electronic equipment manufacturing, prefabricated workshops can provide spacious, bright and flexible production space to meet the reasonable layout of production lines and equipment installation requirements. At the same time, the fast construction speed allows enterprises to quickly expand production scale and adapt to market changes.

Logistics and warehousing: The logistics and warehousing industry has high requirements for space. The large-span design of prefabricated workshop building can provide spacious column-free space for the storage and handling of goods. Moreover, its fast construction speed can meet the needs of logistics companies to quickly build warehouses to cope with the rapid growth of business.

Food processing: The food processing industry has strict requirements on the hygiene and stability of the production environment. The high-quality construction and good thermal insulation performance of prefabricated workshop building can provide a clean, temperature and humidity controlled production environment for food processing. At the same time, the rapid delivery of prefabricated buildings also helps food companies to start production as soon as possible to meet the market’s demand for food supply.

Agricultural field: In agricultural production, prefabricated workshop buildings can be used to build greenhouses, agricultural product processing workshops, etc. Its energy-saving and environmental protection characteristics can provide a suitable environment for the growth of crops, and can also meet the requirements of agricultural product processing for space and environment.

Prefabricated workshop buildings have broad application prospects in manufacturing, logistics warehousing, food processing, agriculture and other fields with their design advantages such as high efficiency, controllable quality, flexibility and environmental protection. With the continuous development of construction technology, prefabricated workshop building will occupy a more important position in the future construction market and provide solid space guarantees for the development of all walks of life.