The perfect combination of warehouse storage units and steel structures

Today in 2025, global logistics and supply chain management are undergoing unprecedented changes. With the explosive growth of e-commerce, intelligent manufacturing, and cross-border trade, traditional warehousing models are no longer able to meet the demands for efficiency, safety, and flexibility. As the “cellular unit” of modern warehousing systems, warehouse storage units have become the key to improving warehousing efficiency due to their standardized, intelligent, and space optimized characteristics. The innovation in this field is closely related to the breakthrough of steel structure technology.

Warehouse storage units: the core infrastructure of modern warehousing

Warehouse storage unit refers to the modular design that divides storage space into independent and expandable storage modules, enabling efficient classification, storage, and management of goods. Its core advantages include:

- Space utilization improvement: By standardizing dimensions and three-dimensional layout, warehouse storage units can increase space utilization by 30% -50%, especially suitable for urban warehousing with limited land resources.

- Flexibility and Scalability: The modular design allows for quick adjustment of storage structures to adapt to different types of goods (such as large, small, cold chain, etc.) and changes in business scale.

- Intelligent management: integrating sensors and automated handling equipment to achieve cargo tracking, temperature and humidity monitoring, and abnormal warning, reducing labor costs.

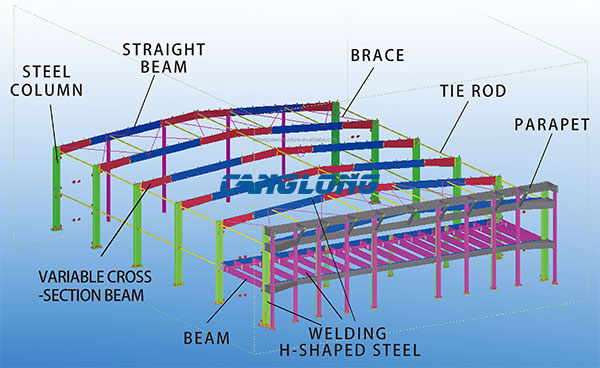

The role of steel structure: the “skeletal system” of warehouse storage units

The efficient operation of warehouse storage units relies on their ‘skeletal system’ – steel structural framework. Steel structures provide solid support for storage units due to their high strength, lightweight, corrosion resistance, and quick installation characteristics:

- Structural stability: The steel structure frame can withstand the load of dense shelves, heavy goods, and automated equipment, ensuring storage safety.

- Modular adaptation: Steel structures can be customized according to the size and functional requirements of storage units, supporting rapid assembly and modification.

- Cost and schedule optimization: Compared with traditional concrete structures, the construction period of steel structures is shortened by more than 40%, and the comprehensive cost is reduced by 20% -30%.

Technological breakthrough of steel structure manufacturers: innovation from materials to design

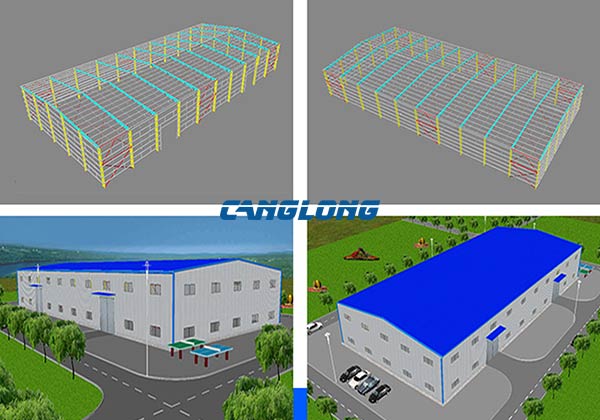

The performance of warehouse storage units is highly dependent on the quality and design of steel structures. As a leading steel structure manufacturer in China, Canglong Group provides full chain solutions for the warehousing industry through continuous innovation

1. Application of high-performance steel

Canglong Group adopts Q355B and above high-strength steel, which has a yield strength 30% higher than ordinary steel, can reduce the weight of the frame, and enhance seismic performance. In addition, the anti-corrosion coating technology developed by the group (such as hot-dip galvanizing+fluorocarbon paint composite process) extends the service life of steel structures to over 25 years in high humidity and corrosive environments.

2. Modular design and intelligent manufacturing

- Parametric modeling: Based on BIM technology, Canglong Group has achieved precise design of storage unit steel structures, supporting rapid generation of construction drawings and material lists.

- Prefabricated production: Through automated production lines, steel structural components (such as columns, beams, and connectors) can be processed with high precision in the factory, with on-site assembly errors controlled within 2mm.

- Flexible adaptability: The same steel structure frame can be compatible with multiple types of storage units (such as rack, pallet, and automated three-dimensional warehouses) to meet customers’ personalized needs.

3. Green and sustainable solutions

Canglong Group responds to the national “dual carbon” strategy and launches a recycled steel recycling system: steel structures can be disassembled and recycled, with a recycling rate of up to 90%, reducing construction waste emissions. At the same time, the photovoltaic integrated steel structure roof developed by the group can achieve self-sufficiency in storage electricity consumption, further reducing operating costs.

Case analysis of Canglong Group: Collaborative implementation of steel structure warehouse and storage unit

Taking a large logistics enterprise as an example, Canglong Group has designed an intelligent warehousing complex for it:

Steel structure frame: adopting large-span portal frame structure, column spacing of 12 meters, net height of 15 meters, maximizing the utilization of vertical space.

Storage unit configuration:

- Floor 1: Heavy duty shelving area (with a load of 5 tons/square meter), used for storing large equipment.

- Floor 2: Automated Stereoscopic Warehouse (AS/RS), which achieves automatic storage and retrieval of goods through AGV robots.

- Mezzanine: Constant temperature and humidity storage unit, equipped with temperature and humidity sensors and automatic control system.

Effect improvement:

- Increase storage capacity by 200% and reduce annual operating costs by 18%.

- The efficiency of goods entering and exiting the warehouse has increased by 40%, and the error rate is approaching zero.

Future trend: Deep integration of intelligent warehousing and steel structures

With the popularization of AI, 5G, and robotics technology, steel structure warehouse will develop towards full automation and high flexibility. Steel structure manufacturers need to further optimize the following directions:

- Integration of Structure and Equipment: Embedding automated tracks, charging piles, and other equipment into steel structure frames to reduce later renovation costs.

- Digital twin technology: Predicting the load, energy consumption, and maintenance requirements of storage units through virtual simulation to achieve full lifecycle management.

- Low carbon material innovation: exploring the application of new environmentally friendly materials such as bamboo steel composite materials and recycled aluminum alloys.

Conclusion: Choosing Canglong Group, ushering in a new era of warehousing

In the wave of transformation in the warehousing industry, collaborative innovation between warehouse storage units and steel structures has become an inevitable trend. As a benchmark enterprise for steel structure manufacturers, Canglong Group provides customized and intelligent warehousing solutions to customers with its full chain service capabilities of “design production construction operation and maintenance”. Whether it is improving space utilization, reducing costs, or responding to green and low-carbon goals, Canglong Group has always driven industry progress with technology, helping enterprises seize opportunities in fierce market competition. Contact Canglong Group immediately for exclusive warehousing optimization solutions!