The construction process of industrial steel buildings

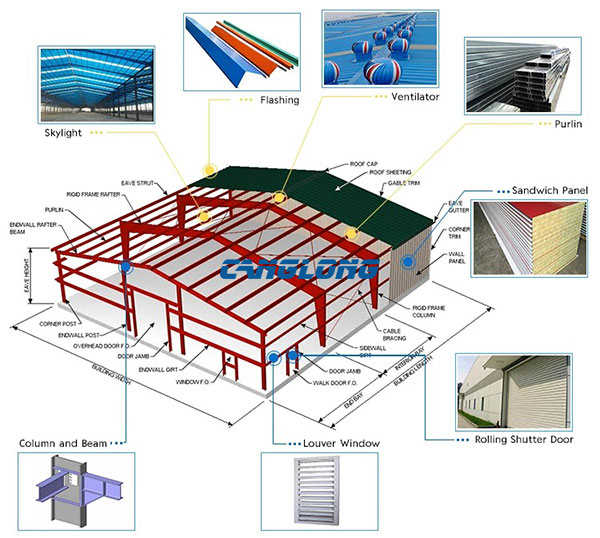

With the rapid development of modern industry, industrial steel buildings have occupied an important position in the construction industry with their unique advantages. It not only has the characteristics of strong structure, short construction period and high cost-effectiveness, but also can meet the needs of modern industry with large span, large space and multi-function. Below, we will introduce the construction process of industrial steel buildings in detail.

1. Preliminary preparation

The construction of industrial steel buildings begins in the preliminary preparation stage. At this stage, designers need to carry out structural design according to the function, structural form and load requirements of the building. This includes determining load distribution, structural layout, material selection and other work. At the same time, it is also necessary to conduct a detailed survey of the construction site to understand factors such as geological conditions and environmental conditions to ensure the rationality and feasibility of the design.

2. Prefabricated component production

The next is the prefabricated component production stage. According to the design drawings, the prefabricated components of the steel structure are made in the factory. This process includes processes such as cutting, welding and drilling of steel. Due to the high strength and good plasticity of steel, prefabricated components that meet the design requirements can be made through precise processing and welding. The precision and quality of these components are crucial to the subsequent installation and the stability of the overall structure.

3. Foundation construction

Foundation construction is an important part of the construction of industrial steel buildings. According to the design requirements, the foundation concrete needs to be poured first. Before pouring, bolts need to be embedded for subsequent connection with the steel structure. The pouring of the foundation concrete needs to be carried out strictly in accordance with the design requirements to ensure the stability and bearing capacity of the foundation.

4. Steel frame installation

When the foundation construction is completed, the installation of the steel frame can begin. This process includes transporting the prefabricated steel frame to the construction site and hoisting it with lifting equipment. During the installation process, the position and angle of the steel frame need to be precisely controlled to ensure that its connection with the foundation and other components is accurate. At the same time, supports and fixings need to be installed to ensure the stability and bearing capacity of the steel frame.

5. Secondary structure and accessories installation

After the steel frame is installed, the secondary structure and accessories need to be installed. These secondary structures and accessories include supports, fixings, connectors, etc., which together with the main steel frame constitute a complete steel structure system. The installation work at this stage also requires precise control of the position and angle to ensure the stability and safety of the entire structure.

6. Welding and fixing

After all parts are installed, welding and fixing work needs to be carried out. This process includes welding the joints of various parts to ensure the stability and load-bearing capacity of the entire structure. At the same time, the welding quality needs to be strictly checked to ensure that the welding quality meets the design requirements.

7. Painting and insulation

The last step is painting and insulation work. After the steel structure is built, painting and insulation treatment are required to improve the durability and insulation performance of the steel structure. The coating material needs to choose corrosion-resistant and wear-resistant materials to ensure that the steel structure can operate stably for a long time. At the same time, insulation treatment is also required as needed to improve the insulation performance of the building.

In general, the construction process of industrial steel buildings is a complex and delicate process. Construction needs to be carried out strictly in accordance with design requirements to ensure that each link meets standards and quality requirements. Only in this way can an industrial steel building with a strong structure, excellent performance and meeting the needs of modern industry be built.