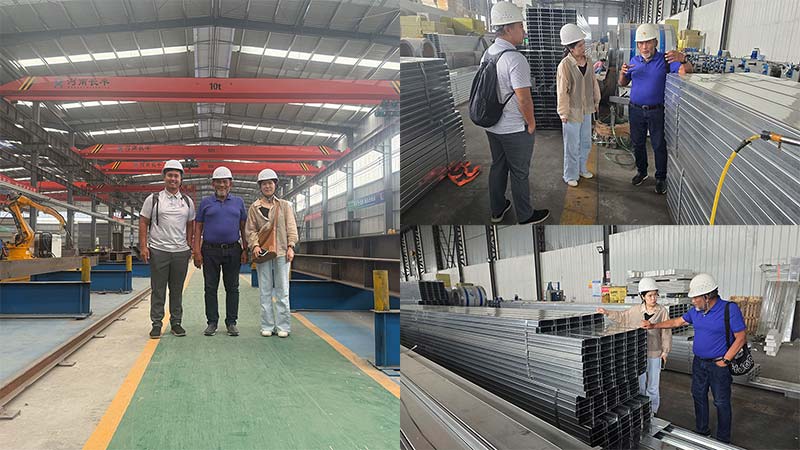

Welcome Philippine clients to visit Canglong factory

Yesterday, Canglong factory welcomed a group of two Philippine customers to visit and inspect. The two sides had in-depth exchanges on steel structure manufacturing and sandwich panel production processes. Accompanied by business manager Sophia, the two foreign guests visited the intelligent steel structure production workshop and the new sandwich panel manufacturing center to experience Canglong Group’s innovative strength in the field of industrial construction.

Entering the fully automatic steel structure production workshop, the spectacular scene of the six-axis industrial robot cluster operation immediately attracted the attention of customers. Under the precise guidance of the laser positioning system, the robotic arm group is collaboratively completing the entire process of cutting, welding, and assembly-in the blue arc light of the plasma cutting table, the special steel plate with a thickness of 50mm is accurately divided into millimeter-level tolerance components.

At the welding station, the robotic arm equipped with a laser tracking sensor performs multi-layer and multi-pass welding with a repeat positioning accuracy of 0.1mm. The flying sparks jump regularly behind the infrared protection curtain, showing the rhythm of modern industrial aesthetics. In the specially designed transparent observation corridor, customers can clearly see through the real-time data dashboard: compared with traditional production lines, the robot integration system has increased the processing efficiency of single components by 240%, and the weld pass rate has been maintained at more than 99.6%.

Moving to the sandwich panel production workshop, customers have personally experienced the entire process of “intelligent manufacturing” of new environmentally friendly panels. The fully automatic rock wool infusion production line is continuously outputting Class A fireproof panels at a rate of 3.5 meters per minute. The vacuum composite process of the bimetallic surface layer and the core material ensures that each square meter of the panel withstands 8000N compressive strength. At the end of the visit, when it was learned that the Canglong sandwich panel had passed the Philippine PNS 2207:2017 certification and was successfully applied to multiple projects in the Philippines, the customer expressed a strong intention to deepen cooperation on the spot.

This visit not only highlights Canglong Group’s advantages in the entire industrial chain from raw material processing to system integration, but also presents the breakthrough progress of China’s intelligent manufacturing in the field of industrial construction to international customers in three dimensions through visual intelligent manufacturing scenes and data-based quality control systems.