What factors should be considered in the design of large industrial workshop?

As an important infrastructure for modern manufacturing and logistics industries, the design of large industrial workshop is not only related to the production efficiency and safety of enterprises, but also affects the overall operating costs and environmental sustainability. During the design process, engineers and architects need to consider many factors to ensure the functionality, economy and safety of the plant. The following will discuss in detail the key factors that need to be considered in the design of large industrial workshop.

First, demand analysis

1. Functional requirements

Before designing a large industrial workshop, a demand analysis is first required. This includes clarifying the functional requirements of the plant, such as the layout of the production line, the configuration of the equipment, the demand for storage space, etc. Different industrial types (such as manufacturing, assembly, logistics, etc.) have different requirements for the space and functions of the factory building. The design team must fully communicate with the customer to ensure that the design can meet their specific needs.

2. Future expansion

Considering the development potential of the enterprise, the design should also consider future expansion needs. This may involve adding production lines, expanding storage space, or setting up new office areas. Therefore, designers need to leave enough space and flexibility to make necessary modifications or expansions in the future.

Second, structural design

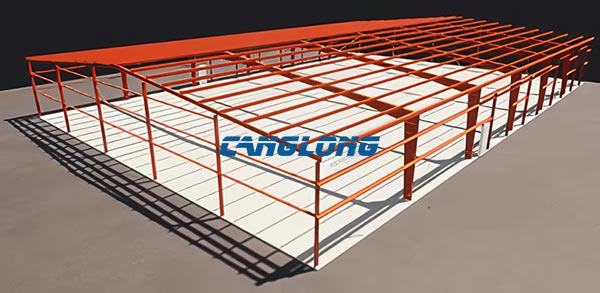

1. Material selection

The structural design of large industrial workshops usually adopts steel structure or concrete structure. Steel structure is suitable for large-span space design due to its high strength and light weight. Concrete structure performs better in fire resistance and earthquake resistance. Designers need to select appropriate materials according to specific needs and budget to ensure the safety and durability of the structure.

2. Load calculation

During the design process, detailed load calculations must be carried out, including static loads and dynamic loads. Static loads mainly include equipment, deadweight and cargo, while dynamic loads involve the activities of operators, equipment operation, etc. Accurate calculation of these loads helps to ensure the structural safety of the plant.

Third, environmental factors

1. Climate adaptability

The design of the factory building must take into account local climatic conditions such as temperature, humidity, wind speed and precipitation. Under extreme climatic conditions, the selection of building materials and structural design need to have sufficient durability and adaptability. For example, in cold areas, the thermal insulation performance of the plant needs special attention to reduce energy consumption.

2. Environmental impact

Designers also need to evaluate the impact of the factory on the surrounding environment, including noise, exhaust gas, wastewater and other emissions. According to relevant environmental regulations, the design plan should include necessary environmental protection measures, such as sewage treatment facilities, exhaust gas emission control, etc., to reduce the negative impact on the environment.

Fourth, safety and health

1. Structural safety

Safety is one of the most important considerations in the design of large industrial plants. Designers must ensure that the building structure can withstand various loads and meet national and local building safety standards. In addition, the setting of safe passages, emergency exits and fire-fighting facilities inside the factory should also be reasonably planned to ensure the safety of personnel.

2. Working environment

A good working environment is essential for the health and productivity of employees. Factors such as natural lighting, ventilation and noise control should be taken into account when designing. For example, setting up large windows to increase natural lighting, or designing an effective ventilation system to maintain air circulation are important measures to improve the working environment.

Fifth, economic efficiency

1. Cost control

Budget control is an important consideration when designing large industrial workshop. Designers need to reasonably select materials and construction methods to reduce construction and operation costs while meeting functional and safety requirements. At the same time, the efficiency of the construction process also directly affects the economic feasibility of the project.

2. Operation cost

In addition to construction costs, the operation cost of the plant is equally important. The design should take into account aspects such as energy consumption, maintenance costs and human resources, and strive to maximize economic benefits in long-term operations. For example, the use of energy-saving technologies and renewable energy systems can significantly reduce energy expenditures.

Sixth, technology and equipment

1. Automation and intelligence

With the advancement of Industry 4.0, automation and intelligence have become important trends in the design of modern industrial plants. Designers should consider how to integrate automation equipment, sensors and information technology into the plant to improve production efficiency and management level.

2. Equipment layout

The reasonable layout of equipment directly affects the production process and efficiency. When designing, it is necessary to scientifically plan the placement of equipment according to the characteristics of the production line to ensure smooth logistics and reduce unnecessary handling and waiting time.

Seventh, regulations and standards

When designing large industrial factory, local building regulations and industry standards must be followed. These regulations usually involve requirements in terms of building safety, fire protection, environmental protection, etc. The design team needs to work closely with relevant departments to ensure that the design plan meets all regulatory requirements to avoid legal risks in the future.

Conclusion

The design of large industrial workshop is a complex and systematic project that requires comprehensive consideration of multiple factors, including demand analysis, structural design, environmental adaptability, safety and health, economy, technology and equipment, regulations and standards, etc. Through comprehensive design considerations, the functionality, economy and safety of the plant can be ensured, providing solid guarantees for the production and operation of the enterprise. In the future, with the continuous advancement of science and technology and changes in market demand, the design of industrial plants will pay more attention to sustainability and intelligence to meet the ever-changing industrial needs.