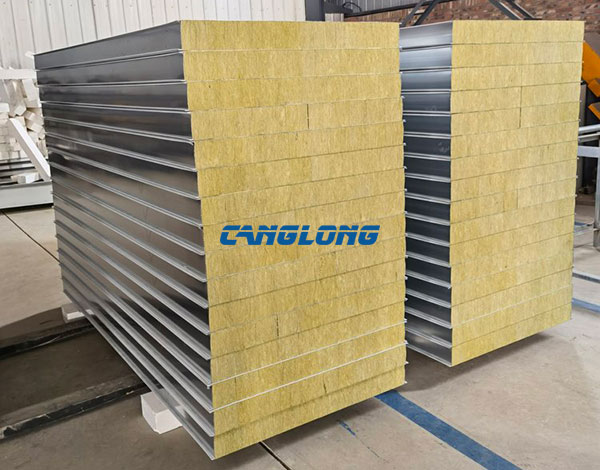

Installation of rock wool sandwich panels in the construction of steel structure sheds

The color steel rock wool sandwich panel can be used to form the wall or roof of the steel structure shed. For small steel structure shed buildings, mobile houses, etc., it is generally only necessary to connect the sandwich panels with a small number of steel keel roof trusses to ensure the integrity and use of the house. For large steel frame buildings, steel structures are generally required as the skeleton of the building. In order to ensure the stability and seismic performance of steel structure buildings.

1. Construction of the wall

a. For the steel structure shed, the rock wool sandwich panel can complete the construction of the wall by connecting the upper and lower ends of the shed with the steel dragon skeleton of the house. The distance between the upper and lower ends of the fixed point is generally about 3m, or according to the specific design. For large-scale steel frame buildings, due to the needs of stability and earthquake resistance, the building skeleton of steel structure is used, and purlins are set at appropriate positions to fix the sandwich panels, and the spacing should generally be ≤3m.

b. If the wall of the sandwich panel needs to be connected to the tower, it should be pressed down. The lap length should not be less than 60mm, and it should be connected and fixed with pull rivets, and the distance between the nails should not be more than 300mm.

c. The channel steel keel should be set on both sides of the door of the steel shed building, the door frame and the channel steel keel should be firmly connected, and the groove-shaped connectors should be preset around the window frame. After the window is aligned, use pull rivets to connect and fix the trough-shaped connector and the rock wool sandwich panel, and use angle aluminum to wrap the corners on both sides of the door and window frame.

d. Reliable sealing measures should be taken at all lap joints of the sandwich panels of the steel structure shed.

2. Construction of the roof

a. For small steel structure buildings, the sandwich panel can complete the roof construction by connecting the front and rear ends of the sandwich panel with the steel dragon skeleton of the house, or according to the specific design. Large-scale steel frame buildings take corresponding solutions for the same reasons that sandwich panels are applied to walls.

b. When the rock wool sandwich panels are lapped along the length of the roof slope, the upper and lower panels should be connected and fixed with steel purlins. Lap length: when the roof slope is not greater than 1/10, the lap length is 300mm; when the roof slope is greater than 1/10, the lap length is 200mm. The overlapping color-coated steel plate parts are connected by rivets, and sealing measures shall be taken for the overlapping joints.

c. The lap joint of the corner board, edge board and flashing board of the steel shed building should follow the prevailing wind and rain direction as much as possible to facilitate the waterproofing of the joints. The lap length should be greater than or equal to 60mm, and should be connected with pull rivets, and the distance between the nails should be less than or equal to 500mm.

d. Holes should be avoided in the roof of sandwich panels. If holes must be opened, they should be as close to the ridge as possible.

e. The fasteners (bolts, blind rivets) of the steel structure shed should be set on the convex wave of the rock wool sandwich panel.